SketchUp Build a Biological Campus for Aldevron in just 14 Acre, Is it Possible?

From its inauguration as a two-person startup developing plasmid DNA to currently navigating the build out of its 14-acre campus, Aldevron has trusted upon SketchUp for many of its architectural and design projects that has helped Aldevron apprehend their architectural goals for the new campus.

Aldevron is a foremost global supplier of plasmid DNA, RNA, and proteins to the research and clinical communities based out of Fargo, North Dakota.

The 14 acre of campus

In the beginning phases, Aldevron is planning to construct out a 14-acre campus in Fargo, North Dakota which is a momentous location for Aldevron founders? native roots. Michael Chambers, who is founding CEO and Executive Chairman, studied at North Dakota State and University in Fargo, hold strong ties to the University and community.

Michael?s vision for the company is to purchase a property near the Fargo Microsoft campus were key components in developing a holistic layout of the master plan.

We are paying attention on the new construction phase adjacent to the existing building. This new facility will meet the manufacture demands of a rapidly growing company. Considering the company?s current growth and its changing spatial needs, we must make the most of the capability of this site to support the growing operation of Aldevron. The master plan includes an expansion of the biologics manufacturing facility, and the development of both an administration and an R&D building.

Campus Design

Quality of best material, composition, and layout of the buildings were persistent in line with the mission goals of the Aldevron project. Innovation sense and forward-thinking ideas were implied in the architecture while maintaining functionality and efficiency from all campus vantage points. Aldevron brand incorporated with thoughtful infusions like clean and modern feel, daylight, views, openness, and adaptability.

The northwest portion of the building, a 25-foot cantilever thrusts out from the two-story form and surround a huge and glossy area. Central courtyard builds in between old and new that generates a physical and visual connection between support and production areas.

The floor perimeter plan connects the office space to gain natural light. We?ve designed discontinuous lounge areas to encourage communication and teamwork that are easily available from all workspaces.

The ground floor is mainly for the manufacturing facility. In contrast with the more public spaces, Design of manufacturing facility is private due to the confidential nature of the work. The existing building connects through a modern glass walkway to the new north production building.

The design of mechanical distribution systems are on full display including airflow, acoustical baffles, and lighting. These systems provide the space of an efficient and industrial environment.

The Design Requirements

The specific requirements of different company and industry require different type of design. Good Manufacturing Practice (GMP) facility is the biggest and most important thing. Dealing with the U.S. Food & Drug Administration (FDA) and other government regulations and documentation are critical to the building layout with a GMP facility.

Incorporating more parking, connecting with the existing building, designing and delivering flexible, collaborative, day lit spaces are other key requirements in this design.

Engineer team strike early the right glazing and daylight balance in the design process. The highly glazed facade permitted for daylight abundance, but we needed not to make issue on glare and overheating. Interior shading devices has to properly control to avoid maintenance problem.

40% ceramic frit on the glass helped to remove heat gain, and glare for maintaining daylight and views. As this campus grows in time to time, seamlessly flow architecture from space to space with the flexibility to adapt for rapid growth. These future requirements in the master plan are permitted while keeping the current work feasible to economical.

Typical design workflow

What is typical design workflow?

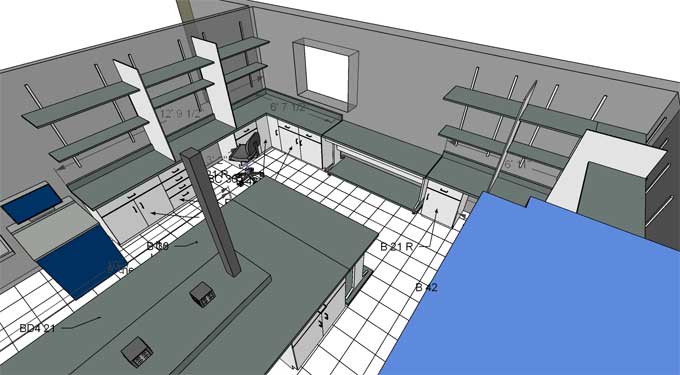

Typical design workflow follows a hybrid approach with SketchUp as the primary design tool. It helps to model the structure straight in Sketch Up or import intricate elements like columns, beams, joists, railing systems, and stairs from Revit into Sketch up.

Getting into the interior development, Import a mix of Revit derived DWG file elements and 3D Warehouse models. Customize the design based on the client?s requirements and brand with all the essentials in place.

What are the benefits of using Sketch Up in the Aldevron project?

Sketch Up allows us to quickly get our design ideas out into 3D.We design in a short period efficiently and accurately. We have to come up with the exterior version and animation of the master plan schematic design concept in a month.